The art of Japanese cutlery manufacturing began in Seki nearly 1000 years ago and Mcusta is proud to keep the tradition alive. At its factory in Seki, Japan the company produces fine cutlery by combining various machine processes with a custom hand-finish. Each knife undergoes the whole process with an exquisite level of artistry and excellence of design.

FORGING

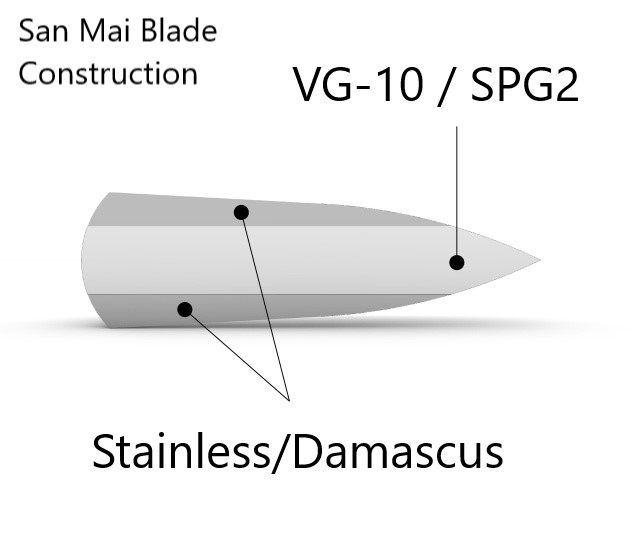

Mcusta uses high quality Japanese steels for its blades. These include VG-10 and VG-10 core Damascus as well as San Mai SPG2 powder steel. Damascus steel patterns are highly decorative. Many Mcusta and Zanmai blades utilize the unique beauty of Damascus. With our original forging machine, we perform the forging process, making full use of dimensional accuracy, hammering and other forging processes.

Our Damascus blades feature a VG-10 core that is forge welded inside of two outer layers of stainless Damascus steel. These decorative outer layers are made by repeatedly folding two different types of stainless steel together and forge welding them by hand until 16 thin alternating layers are created. This type of forging produces a flexible yet durable blade that is ideal for all types of cutting requirements.

SPG2 powder steel is a Japanese super steel. It has a similar edge retention as S35VN, and when made in the form of San Mai construction it has the elegance of the traditional katana hamon.

LASER-CUTTING

The materials are cut by Laser, making it possible to cut out complex shapes accurately, and at high speeds. Unlike press stamping, it does not generate extra stress that causes strain inside. The laser is ideal in handling a wide variety of products in small quantities.This also makes it easier to modify the shape of the cut.

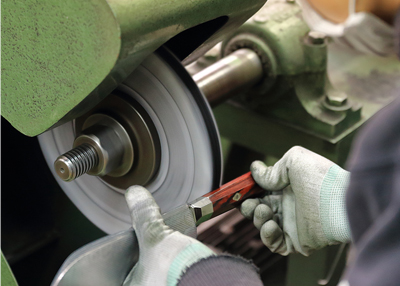

BLADE GRINDING

After the blade is initially processed, it is ground by machine into an accurate thickness, angle, and shape. Using the latest grinding machine, we finish each one perfectly. There are several grinding processes, and each process from rough grinding to finishing is done with strict quality checks. The hamaguri blade is also completed in this process.

HEAT TREATING

Heat treatment hardens the steel and makes the blade perform in the high-standard we have come to expect from quality craftsmanship. Each blade goes through this process, to ensure its reliability. It can be said that the most important step for blades is heat treatment. In addition to paying close attention to temperature control, sub-zero treatment is applied to stabilize the structure.

SURFACE TREATMENT AND POLISHING

The Damascus pattern or san mai core stands out once a surface treatment such as acid etch is added. Then, the unique patterns comes out in high relief after the surface is polished.

MACHINING

Each item we offer is made by combining small parts to make up the whole. It is indispensable to the final product that each component is cut precisely in order that all pieces work in harmony with each other. Using a machine to do such jobs as rough-cutting the handle, or boring hole positions for screws is both accurate and efficient.

HAND-PROCESSING

After the rough cuts are made, each piece undergoes a hand-machining process, which adds an individual mark to each knife. Sometimes there are shapes that are difficult to cut by machine, and these shapes are better executed by the human hand.

Each one is finished with keen attention by skilled craftsmen. We change the polishing method depending on the product, and consider the beauty of appearance and ease of use. Handle processing is also done in-house, and there are several steps to accomplish until reaching the final stage. One of our features is the wide variety of handles.

ASSEMBLY AND ADJUSTMENT

Each item we offer is assembled individually using all the various small parts that have undergone the processes mentioned above. Unless each piece is precisely formed using the previous steps, the knife cannot be assembled. Here is where the movement and play are adjusted by the manual tightening of screws.

FINISH

Finishing the assembled product is a job done by hand, because, depending upon the shape or materials of the model in question, there will be a different set of tools and methods needed to obtained the desired effect.

SHARPENING

Using a large rotating flat whetstone and a sprinkle of water, our skilled artisans sharpen each blade one by one. Our incredibly sharp edges are made in this way without loss of hardness. Mcusta blades are the sharpest out of the box knives in production.

CARE AND INSPECTION

Finally, it requires a scrutinizing eye to analyze the blade-opening movement and to remove the polishing compounds that may adhere to the materials during the finishing and sharpening process. The lock will be inspected for reliability, as well as blade condition and position. There is a last wipe-down and the final product is wrapped and packaged with care.

Mcusta pays detailed attention to the whole production process and takes great pride in delivering the highest quality Japanese knives to valued customers throughout the world.

Mcusta pays detailed attention to the whole production process and takes great pride in delivering the highest quality Japanese knives to valued customers throughout the world.

US Dollar

US Dollar